Utilization of the MicroClime Environmental Lid to Reduce Edge Effects in a Cell-based Proliferation Assay

John Lesnick, Linda Orren, Noёl RuppertAbstract

In this study, we demonstrate the benefit of utilizing the MicroClime Environmental Lid to reduce edge effects in a functional cell-based assay by measuring the mitigation of evaporation of fluid in reaction wells. The value of using MicroClime Lids is shown for 384-well and 1536-well plates in both standard gravimetric QC assessments and functional cell based viability assays. The results demonstrate reduced evaporation, the ability to miniaturize and extend proliferation assays, while generating better growth rates, and higher quality data with reduced CV’s.

Introduction

Cell-based assays have become an essential tool for a wide variety of applications in both academia and industry-based research. These assays allow researchers to analyze complex cellular functions of intact pathways and the interaction between pathways. The ability to interrogate pathway-specific drug interaction provides more data compared to biochemical assays and allows higher throughput compared to in vivo studies.

High density microplates enable miniaturized assay volumes, increased productivity, and reduced assay costs for functional cell-based assays. However, cell culture in microplates is often affected by edge effects where perimeter wells of plates are subject to evaporation during long periods of incubation. This phenomenon can lead to changes in media pH, osmolality, and the concentration of the media constituents with potentially problematic consequences for cell-based assay results.

MicroClime Environmental Lid

The MicroClime Environmental Lid minimizes edge effects and preserves the concentrations of solutions in microplate wells. The MicroClime Lid incorporates a unique, fluid-absorbing matrix. The absorbed fluid creates a vapor barrier that protects the sample from the exterior environment, preventing evaporation from the plate, especially near the edges of the microplate. The MicroClime Lid is compatible with robotic plate lidding systems and can be filled with a variety of fluids, using either a hand-held syringe, pipettor, or automated bulk fillers.

Figure 1. MicroClime Environmental Lid from top view.

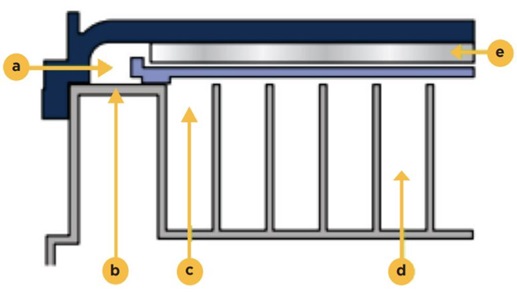

The liquid in the MicroClime Environmental Lid evaporates to fill the headspace with a vapor-saturated atmosphere, retards the evaporation in the wells, and acts as a barrier to infiltration of external gases. In Figure 2:

|

Figure 2. The MicroClime Environmental Lid seated on a microtiter plate: cut out of cross section view. |

a and c: Regions of saturated vapor b: Sealing surface d: Microplate well e: Fluid-saturated polypropylene felt |

Methods

Cell Culture

PC-3 cells were maintained in growth media in log phase prior to plating. Cells were detached from flasks with Versene , centrifuged to pellet, and resuspended in growth media to 1.5E5 cells / ml and 1E5 cells / ml prior to cell plating.

384-Well Proliferation Assay

Cell suspension at 1.5E5 cells / ml was dispensed to 384-well black TC-treated plates with a Multidrop Combi Reagent Dispenser at 10 µL per well (3.84 mls per plate) for an initial seeding density of 1500 cells per well. Cell plates were weighed after seeding and before CellTiter-Glo addition. On Day 0 and every 24 hrs. for five days, 10 µL of CellTiter-Glo was added to the assay plate(s), assay plate with control lid, and an assay plate with MicroClime lid, incubated for 30 mins. and read on the BMG LABTECH PHERAstar FS plate reader to measure luminescence. Day 0 plating reference CV was 4.6%.

1536-Well Proliferation Assay

Cell suspension at 1E5 cells /ml was dispensed to 1536-well black TC-treated plates with a Multidrop Combi Reagent Dispenser at 5 µL per well (7.68 mls per plate) for an initial seeding density of 500 cells per well. Cell plates were weighed after seeding and before CellTiter-Glo addition. On Day 0 and every 24 hours for five days, 3 µL of CellTiter-Glo was added to the assay plate(s), assay plate with control lid, and an assay plate with MicroClime lid, incubated for 30 minutes and read on the BMG LABTECH PHERAstar FS plate reader to measure luminescence. Day 0 plating reference CV was 21%.

Experiment 1

Evaporation Measured Gravimetrically

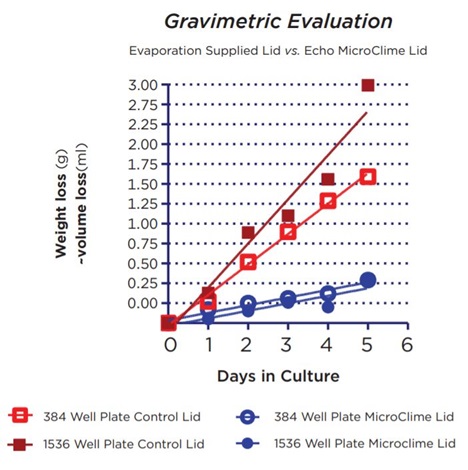

Assay plates were incubated in a standard cell culture incubator over a five day period. The MicroClime Environmental Lid minimizes loss of fluid volume measured by weight compared to control lids supplied by the plate vendor. The rate of evaporation is greater in assay plates with control lids. The rate / slope of the MicroClime plates is 0.09 g/day while the 384-well control plates rate /slope is 0.38 g/day and 0.56 g/day for the 1536-well control plates.

All assay plates were weighed on Day 0 after cell plating. On each day of evaluation, the assay plate was reweighed and compared to the day zero weight and the change in measured weight was plotted. Day 0(g) - Day X(g) = delta (g).

Figure 3. Evaporation measured gravimetrically.

Experiment 2

Whole Plate Cell Proliferation Assay

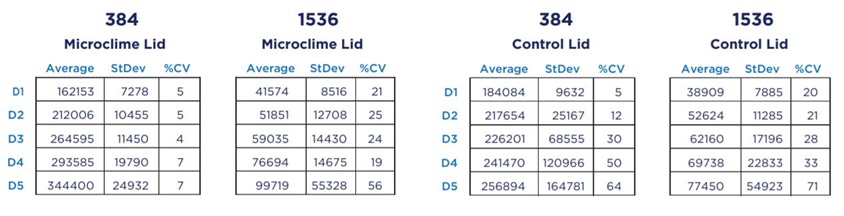

384-well and 1536-well PC-3 cell plates with either control or MicroClime lids were assayed for cell viability with CellTiter-Glo each day for five day. Plate Average, Standard Deviation and % CV calculated n=384 or n=1536 wells (Figure 4).

Figure 4. Whole plate cell proliferation assay statistics.

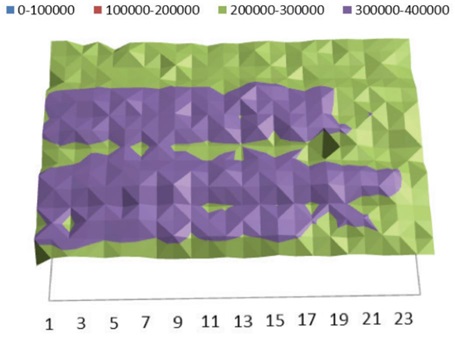

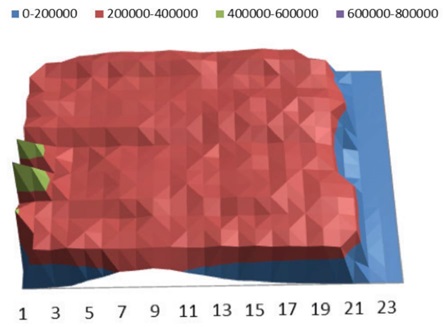

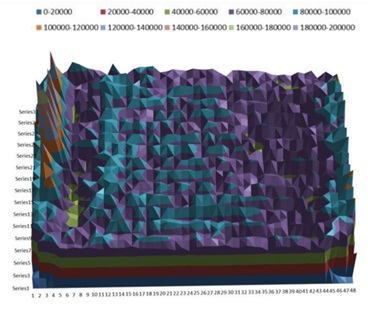

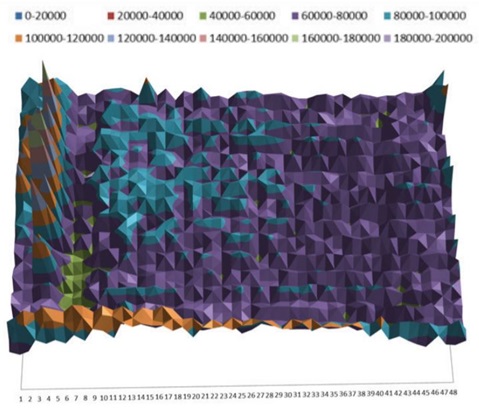

Edge effects in control lid plate results account for higher CV’s and loss of wells to evaporation. Representative assay surface / heat map plots for 384-well and 1536-well assay plates with MicroClime Lids and standard lids.

Figures 4 (A-D). Day 4 whole plate cell proliferation assay surface / heat map plot. Edge effect in control lid plate results account for higher CV’s and loss of wells to evaporation.

Figure 4 (A): 384-well MicroClime Environmental Lid

Figure 4 (B): 384-well Control Lid

Figure 4 (C): 1536-well MicroClime Environmental Lid

Figure 4 (C): 1536-well Control Lid

Discussion

A common work-around to address edge effects is to use only the center of the microplate for reaction wells. The use of MicroClime Environmental Lids enables you to use all the wells in your microplate, from edge to center by significantly reducing edge effects due to evaporation. This can increase your microplate productivity by up to 60%.

Another method commonly used to address edge effects is to increase the volume of reaction wells to mitigate the effect of evaporation. This is often the case for cells with reduced doubling times. Using the MicroClime Lid allows 384-well proliferation assays to run to >=5 days increasing signal window and enables testing of slowly dividing cell lines. The reduction in assay and CellTiter-Glo additions to 10 µL decreases costs by 2.5X or 60% per 384-well plate. The results indicate that reduced CV’s and better cell growth rates can lead to better quality results using the MicroClime Environmental Lid.constituents with potentially problematic consequences for cell-based assay results.

Materials

| Consumables/Reagents | Manufacturer | Part Number |

| MicroClime Environmental Lid, sterile | Beckman Coulter Life Sciences | #LLS-0310 |

| PC-3 Cell Line | ATCC | #CRL-1435 |

| Growth Media RPMI 1640 supplemented with 10% FBS and 100 U/ml Pen/Strep | ||

| 384-well Black TC-Treated Plates | BD Falcon | #353962 |

| 1536-well Black TC-Treated Plate | Corning | #3726 |

| CellTiter-Glo Viability Assay | Promega | #G7570 |